Our Process

See All Flooring Options

THE CANADA CHEMICALS AND COATINGS 5-TIER SYSTEM

At Canada Chemicals and Coatings, we take pride in our work. Through thousands of successful projects, our experienced specialists have learned to deal with any issue that may arise to ensure that you get the floor you want! Whether you’re looking for Epoxy Contractors In Vancouver or need Residential Epoxy Contractors, our team is here to deliver top-quality results tailored to your needs.

Tier 1: Floor Grinding and Surface Preparation

Concrete grinding involves the smoothing of rough concrete surfaces. Utilizing an abrasive tool with a diamond attachment, the rough surface is meticulously prepared. This process eliminates all coatings, stains, and surface cracks, including the top layer of concrete, providing a solid foundation for the application of Canada Chemicals and Coatings epoxy flooring products.

Tier 2: Filling Cracks and Repairing Pits

Ensuring a seamless epoxy finish on your floors is pivotal, and that begins with filling cracks and repairing pits. At Canada Chemicals and Coatings, we employ Penetron fast-curing cement products to guarantee your concrete is perfectly level before applying the epoxy.

Any protrusions or uneven areas on the concrete surface are smoothed down, ensuring a flawlessly even result.

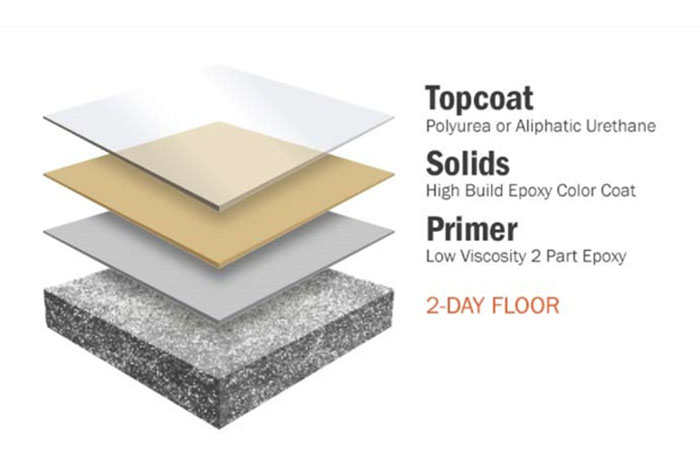

Tier 3: Application of Colored Epoxy Primer Coat

Preparing the surface for subsequent epoxy coats involves sealing the floor with a primer. When done meticulously, this establishes a highly durable bond.

Our skilled team, using a 2-part polyurethane epoxy system, blends the epoxy with a pigment tailored to the overall design. This mixture is then expertly applied using a squeegee and roller to achieve complete coverage.

Tier 4a: Decorative Flakes

While the primer is still wet, a team member will evenly distribute decorative chips directly onto the base coat. At Canada Chemicals and Coatings, we ensure thorough coverage by spreading more than required during this step.

Once cured, any excess flake material is meticulously removed using a vacuum in preparation for the final stage.

Tier 4b: Metallic Finish

Our team pours the chosen epoxy design directly onto the wet primer to achieve the desired thickness, which has been pre-measured to ensure an even 40 mils thickness across the floor.

Tier 4c: Industrial Sand Epoxy

The selected grit of sand is cast directly into the primer and then back-rolled to guarantee an even distribution. Onsite, the tensile strength is pre-tested before the application to the larger area.

To achieve a uniform coat, an additional base coat is applied at this stage, along with another cast of sand. This imparts a durable, non-slip finish suitable for industrial purposes.

Tier 5: Clear Polyaspartic Topcoat

The concluding step involves the even application of the final clear topcoat using rollers and tape. This distinctive process, exclusive to Canada Chemicals and Coatings, guarantees a topcoat finish that is not only more durable but also consistently impeccable.

For optimal results, it is advisable to allow the floor a curing time of 24 hours before foot traffic and 48 hours before the introduction of light vehicular traffic.

The site is now cleaned up and the equipment and materials taken away.

Get a Quote For Your Project

Our floors exude durability. To underscore our confidence, we back every Canada Chemicals and Coatings floor with a robust 3-year warranty, safeguarding against flaking, peeling, and blistering.

WHAT DO WE BRING TO THE TABLE?

We have the experience and knowledge to make your job a success. We have the perfect combination of knowledge, experience coupled with high quality products to make every job a success!

ONGOING SUPPORT

QUALITY PRODUCTS

EXPERT ASSISTANCE

QUALITY WORKMANSHIP

EXPERIENCE/KNOWLEDGE

SUPERIOR SERVICE

Have a question or want to book an appointment? Get in touch today!

How Can We Help?

We can assist you with your all aspects of your job. From Design, Installation and Maintenance we provide everything you need under one roof.